Apple just announced a massive $100 billion acceleration of its US investment plans. This pushes their total commitment over the next four years to a staggering $600 billion. An ambitious new American Manufacturing Program (AMP) is designed to pull even more of Apple’s critical supply chain and advanced manufacturing onto American soil.

Apple’s footprint is already huge. They partner with thousands of suppliers across all 50 states, supporting over 450,000 jobs. But they’re not stopping there. Within four years, Apple plans to directly hire 20,000 more people in the US, with the vast majority focused on cutting-edge fields like R&D, silicon engineering, software development, AI, and machine learning.

American Manufacturing Program (AMP)

So, what’s the AMP all about? This program is Apple’s proactive push to fund and incentivize more manufacturing right here. They’ve named their first partners: heavy-hitters like Corning, Coherent, GlobalWafers America, Applied Materials, Texas Instruments, Samsung, GlobalFoundries, Amkor, and Broadcom. This builds on July’s commitment to buy American-made rare earth magnets from MP Materials.

AMP funding is supercharging Apple’s partnership with Corning. It will bring the world’s largest and most advanced smartphone glass production line to Harrodsburg, Kentucky. Soon, every iPhone and Apple Watch globally will feature Kentucky-made cover glass! Plus, a new Apple-Corning Innovation Center is opening there, too.

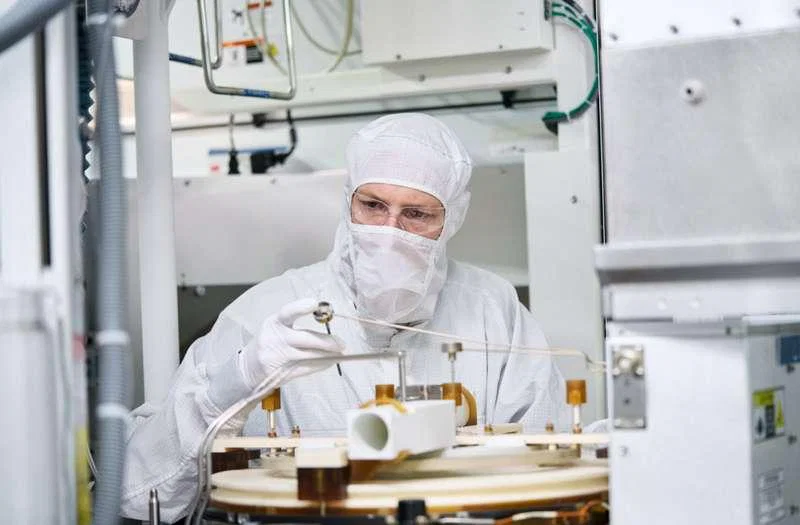

Apple also signed a new multiyear deal with Coherent for the VCSEL lasers essential for Face ID and other features on iPhones and iPads. This critical work happens at Coherent’s facility in Sherman, Texas. MP Materials is significantly expanding its Fort Worth, Texas, facility and establishing a cutting-edge rare earth recycling line in Mountain Pass, California.

Building an End-to-End US Silicon Supply Chain

Apple is actively building a comprehensive, end-to-end silicon supply chain within the US. Partners now cover every key stage. This homegrown chain is projected to produce over 19 billion chips for Apple products in 2025 alone! This includes cutting-edge chips from TSMC’s new Arizona fab, where Apple is the first and largest customer.

Apple COO Sabih Khan emphasized this commitment: “We’re committed to supporting U.S. suppliers involved in every key stage of the chip-making process. We want America to lead in this critical industry.”

New & Expanded Facilities Powering the Future

Beyond components, Apple is building new things with its US investments. Construction started this year in Houston on a factory for advanced Apple servers, with test units already produced. Mass production begins in 2026. These servers, previously made overseas, are crucial for Apple Intelligence and the groundbreaking Private Cloud Compute security architecture.

Education meets manufacturing in Detroit, where the new Apple Manufacturing Academy opens on August 19th. It will offer consultations and courses to help small and medium-sized businesses integrate advanced manufacturing and AI into their operations.

Apple is expanding its Maiden, North Carolina, data center (already backed by over $5 billion) to support growing services like iCloud, the App Store, Apple Music, and crucially, Apple Intelligence. And yes, it’s 100% renewable. Additional data center expansions are underway in Iowa, Nevada, and Oregon.

Apple’s second campus in Austin, Texas, continues to rise. With over 13,000 Texas employees already, the expansion includes three new buildings featuring major R&D lab space for Hardware Engineering, Hardware Technology, and Software Engineering teams. This $600 billion investment is truly nationwide.

Maybe you would like other interesting articles?