A metal 3D printer is an advanced manufacturing machine that builds complex, high-strength metal parts layer by layer using digital designs. Unlike traditional subtractive methods like machining, which cut away material, metal 3D printing, also known as additive manufacturing, fuses fine metal powders or wires using lasers, electron beams, or binder jets to create fully dense, precision-engineered components. This technology enables the production of intricate geometries that would be impossible with conventional techniques, making it a game-changer for industries like aerospace, automotive, and medical implants.

The process typically involves techniques such as Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), or Electron Beam Melting (EBM), where a high-powered laser or electron beam melts metal powder to fuse it into a solid structure. This additive approach not only reduces waste but also enables rapid prototyping, customization, and complex designs that push the boundaries of traditional manufacturing. As metal 3D printing continues to evolve, it’s transforming how engineers and manufacturers bring innovative ideas to life with unmatched speed and precision.

If you’re considering buying a metal 3D printer, chances are you’re looking to bring cutting-edge innovation directly into your production process. The decision to invest in this powerful technology often stems from a desire to reduce lead times, streamline prototyping, or manufacture complex metal parts that traditional methods struggle to produce efficiently. Whether you’re part of a small-scale engineering firm or a growing manufacturing company, owning a metal 3D printer gives you the flexibility to experiment with designs, test ideas faster, and ultimately gain more control over your production cycle. Here, we provide some of the best metal 3D printer recommendations that may suit your needs.

Table of Contents

- Markforged Metal X

- EOS M 290

- Desktop Metal Studio System 2

- SLM Solutions NXG XII 600

- GE Additive Concept Laser M2 Series 5

- 3D Systems DMP Flex 350

- Renishaw RenAM 500Q

- HP Metal Jet S100

- Xact Metal XM300G

- Farsoon FS421M

List of Top 10 Metal 3D Printers

1. Markforged Metal X

Technology: Bound Metal Deposition (BMD)

Build Volume: 300 x 220 x 180 mm

Materials: 17-4 PH, H13, A2, Copper, Inconel 625

Price: ±$99,500

Why it’s recommended:

The Metal X is perfect for medium-sized businesses seeking an easy-to-use, cost-efficient entry into metal 3D printing. Its bound metal deposition technology is safer and more office-friendly than traditional powder-based systems. With low overhead and reliable Eiger software integration, the Metal X streamlines metal part production without requiring a dedicated industrial facility.

2. EOS M 290

Technology: Direct Metal Laser Sintering (DMLS)

Build Volume: 250 x 250 x 325 mm

Materials: Aluminum, Titanium, Stainless Steel, Cobalt Chrome

Price: ±$700,000

Why it’s recommended:

A staple in industrial metal additive manufacturing, the EOS M 290 offers unmatched material versatility and proven repeatability. It’s ideal for businesses scaling up production or entering regulated industries like aerospace or medical, where part consistency and certification are essential.

3. Desktop Metal Studio System 2

Technology: Bound Metal Deposition (BMD)

Build Volume: 300 x 200 x 200 mm

Materials: Stainless Steel (17-4PH, 316L), Tool Steels

Price: ±$200,000

Why it’s recommended:

Designed for office-friendly operation, the Studio System 2 eliminates the need for hazardous loose powders or lasers. With a simplified two-step process (print and sinter), it’s an excellent choice for businesses needing functional prototypes and low-volume production parts without a steep learning curve.

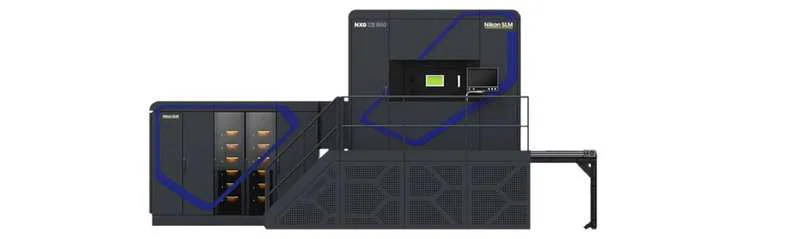

4. SLM Solutions NXG XII 600

Technology: Selective Laser Melting (SLM)

Build Volume: 600 x 600 x 600 mm

Materials: Titanium, Aluminum, Nickel Alloys, Steel

Price: ±$600,000

Why it’s recommended:

One of the most powerful metal 3D printers on the market, the NXG XII 600 features 12 lasers and is built for industrial-scale production. Perfect for large enterprises in automotive or aerospace, it drastically reduces print time for massive, high complexity parts, delivering one of the best ROI potentials at scale.

5. GE Additive Concept Laser M2 Series 5

Technology: Laser Powder Bed Fusion (LPBF)

Build Volume: 250 x 250 x 350 mm

Materials: Stainless Steel, Titanium, Nickel, Aluminum

Price: ±$800,000

Why it’s recommended:

With advanced process monitoring, automation-ready features, and full digital twin capabilities, the M2 Series 5 is ideal for businesses requiring rigorous process control and part traceability. It supports industries with strict quality assurance standards and long-term production goals.

6. 3D Systems DMP Flex 350

Technology: Direct Metal Printing (DMP)

Build Volume: 275 x 275 x 420 mm

Materials: Titanium, Stainless Steel, Nickel Alloys

Price: ±$575,000

Why it’s recommended:

The DMP Flex 350 delivers precision and repeatability, thanks to its vacuum chamber and fine powder control. It’s highly suitable for medium to large businesses looking to produce complex geometries with demanding tolerances, particularly in medical implants and aerospace components.

7. Renishaw RenAM 500Q

Technology: Laser Powder Bed Fusion

Build Volume: 250 x 250 x 350 mm

Materials: Titanium, Aluminum, Cobalt Chrome

Price: ±$850,000

Why it’s recommended:

The RenAM 500Q is a quad-laser system designed for high productivity and part quality. Its modular platform allows businesses to customize it for their specific application, and Renishaw’s strong metrology background ensures it integrates seamlessly with quality assurance workflows.

8. HP Metal Jet S100

Technology: Binder Jetting

Build Volume: 430 x 309 x 200 mm

Materials: Stainless Steel (316L, 17-4PH)

Price: ±$399,000

Why it’s recommended:

Targeted at volume production, the Metal Jet S100 offers exceptional speed, precision, and cost-effectiveness for batch manufacturing. HP’s binder jetting technology is non-reactive, enabling faster throughput and lower operational risk, ideal for businesses entering metal AM with mass-production goals.

9. Xact Metal XM300G

Technology: Laser Powder Bed Fusion

Build Volume: 254 x 330 x 330 mm

Materials: Stainless Steel, Titanium, Aluminum

Price: ±$200,000

Why it’s recommended:

Xact Metal offers powerful industrial features at a competitive price, making the XM300G ideal for mid-sized businesses expanding into metal printing. With dual laser options and simplified software, it balances performance and affordability for shops needing dependable productivity without excessive overhead.

10. Farsoon FS421M

Technology: Selective Laser Melting (SLM)

Build Volume: 425 x 425 x 420 mm

Materials: Titanium, Aluminum, Steel, Nickel

Price: ±$200,000

Why it’s recommended:

Farsoon’s FS421M is a robust open-platform system known for high-speed scanning and thermal stability. Suited for heavy-duty applications, it allows material and process customization, giving large enterprises the flexibility to tailor production based on part requirements or proprietary alloys.

Advice before buying a metal 3d printer

If you’re considering investing in a metal 3D printer, it’s essential to start by carefully assessing your specific production needs and long-term goals. Metal additive manufacturing offers incredible opportunities from rapid prototyping to full-scale production, but it’s not a one-size-fits-all solution. Before leaping, evaluate the types of metals you plan to use, the required build volume, and the precision needed for your applications. Additionally, consider the production speed and throughput to ensure the machine aligns with your workflow demands. Keep in mind that the initial purchase price is just the beginning; ongoing costs such as materials, maintenance, software, and operator training can significantly impact your overall budget.

Another critical factor is to research the different technologies and manufacturers thoroughly. Metal 3D printing technologies vary from laser powder bed fusion to binder jetting, and each has strengths suited for different use cases. Look for machines with proven reliability, good customer support, and scalability options so you can grow your capabilities as your needs evolve. Don’t forget to request demonstrations or pilot runs to test how the printer handles your specific materials and designs. By taking a thoughtful, informed approach, you’ll ensure your investment drives innovation and efficiency without unexpected hurdles.

Maybe you like other interesting articles?