Samsung, working with NVIDIA, plans to build an “AI Megafactory” equipped with over 50,000 GPUs. The project is part of Samsung’s strategy to accelerate development in chips, mobile devices, and robotics through AI-driven production.

Samsung says the AI Factory will move past standard automation to serve as a unified, intelligent platform. The system will tie together all stages of chip manufacturing, from early design and complex fabrication steps to machine control and quality checks. AI will play a central role, monitoring data, predicting faults, and optimizing production as it happens.

Rooted in a partnership that stretches back over two decades, Samsung and NVIDIA’s collaboration began when Samsung’s DRAM powered NVIDIA’s first-generation graphics cards. The relationship has since evolved into a foundry partnership spanning multiple product lines.

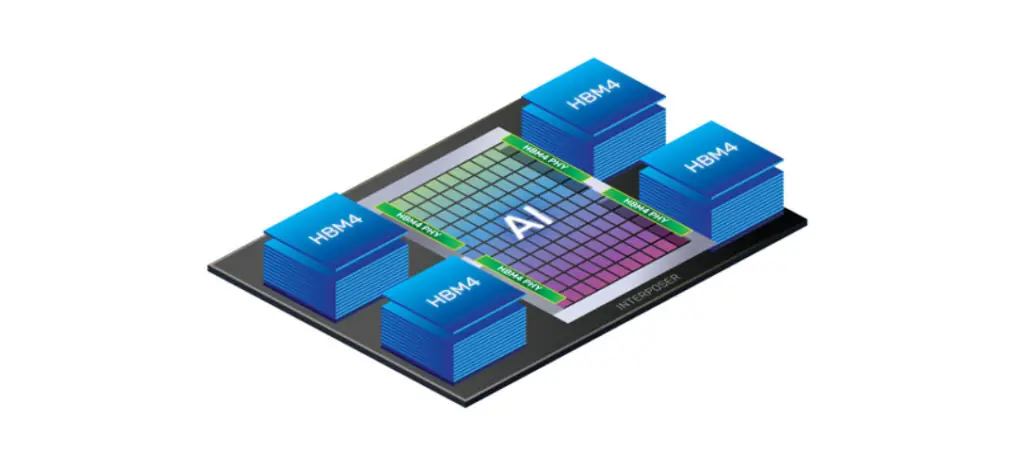

Right now, Samsung and NVIDIA are teaming up on HBM4, the next leap in high-speed memory. Samsung’s new design focuses on top-tier bandwidth and low power use, both crucial for the next wave of AI hardware. Built with the company’s 6th-gen 10nm-class DRAM and a 4nm logic base, HBM4 can hit speeds up to 11Gbps, outpacing most of what’s on the market today.

Samsung says it will continue supplying the market with a broad lineup of next-generation memory technologies, such as HBM, GDDR, and SOCAMM, complemented by its advanced foundry services. The company positions this effort as a way to boost innovation and scalability throughout the global AI supply chain.

Over the next few years, Samsung plans to grow its AI Factory with help from NVIDIA’s accelerated computing tech. One big piece of that is building digital twins, lifelike virtual versions of its chip plants using NVIDIA Omniverse. With these, Samsung can test ideas, catch problems, and fine-tune operations in a digital space before touching real equipment.

Samsung reports a 20-fold performance increase in its optical proximity correction process after adopting NVIDIA’s cuLitho and CUDA-X libraries for computational lithography. The upgrade enables AI to detect and correct minute circuit variations more quickly and precisely, cutting design cycles significantly. Both companies are also teaming up with EDA vendors to build GPU-accelerated design automation tools for future chip development.

Samsung’s latest manufacturing intelligence stems from its long-running AI research. The company’s proprietary models, already deployed across a global base of more than 400 million devices, are now being embedded within its production infrastructure. Powered by NVIDIA’s accelerated computing stack and the Megatron framework.

Samsung is also applying its AI expertise to robotics. Using NVIDIA’s RTX PRO 6000 Blackwell platform, the company aims to push automation and humanoid robotics to the next level. With support from platforms like NVIDIA Jetson Thor, Samsung is training robots to better understand their surroundings, make decisions on the fly, and operate safely alongside humans. These technologies will be integrated into the AI Factory ecosystem, allowing AI and robotics to work together seamlessly.

In the next phase of their alliance, Samsung and NVIDIA are joining forces with Korean telecom operators, universities, and research bodies to develop AI-RAN (Artificial Intelligence, Radio Access Network). By embedding AI computing directly into mobile network infrastructure, AI-RAN will enable real-time data processing and inference for edge devices like robots, drones, and industrial systems.

Before, Samsung and NVIDIA proved the concept by merging Samsung’s network software with NVIDIA’s GPUs. Now, they’re taking that success further, working to turn AI-RAN into one of the key technologies shaping the next era of connectivity.

Maybe you would like other interesting articles?